Wafers business

The wafer business typically refers to the production and sale of semiconductor wafers. Semiconductor wafers are thin slices of semiconductor materials, such as silicon, that serve as the base for manufacturing integrated circuits (ICs) and other electronic components. These wafers undergo various processes, including deposition, lithography, etching, and doping, to create the intricate circuitry and components needed for electronic devices.

The wafer business is a crucial part of the semiconductor industry, which plays a significant role in various sectors, including consumer electronics, telecommunications, automotive, healthcare, and industrial applications. As technology advances and demand for more powerful and efficient electronic devices increases, the demand for semiconductor wafers also grows.

Companies in the wafer business can include semiconductor manufacturers, foundries, and specialized wafer fabrication facilities. These companies typically produce wafers of different sizes and specifications to meet the requirements of their customers, which can range from large electronics manufacturers to smaller component suppliers.

The wafer business is highly competitive, and companies must continually invest in research and development to stay at the forefront of technological advancements. Additionally, factors such as economies of scale, production yield, and manufacturing efficiency play significant roles in the profitability of wafer production.

It's worth noting that "wafer" can also refer to other types of products, such as chocolate wafer biscuits or wafer cones used in ice cream. These products fall under the realm of the food industry and are not directly related to the semiconductor wafer business.

Types of Semiconductor Wafers: Semiconductor wafers come in different sizes, the most common being 200mm (8 inches) and 300mm (12 inches) in diameter. The size of the wafer affects the number of chips that can be produced from it, with larger wafers allowing for higher chip density and increased production efficiency.

Foundries and Fabless Companies: In the semiconductor industry, there are two main types of companies involved in the wafer business: foundries and fabless companies. Foundries specialize in manufacturing wafers and chips for other companies based on their designs, while fabless companies focus on chip design and outsource the manufacturing process to foundries.

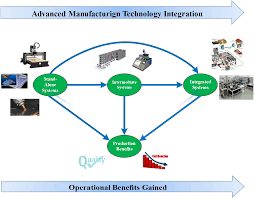

Advanced Manufacturing Processes: The production of semiconductor wafers involves sophisticated manufacturing processes. These include photolithography, where light is used to transfer circuit patterns onto the wafer's surface; chemical and physical deposition, which involves applying thin layers of material onto the wafer; and etching, which removes unwanted material to form the desired circuitry.

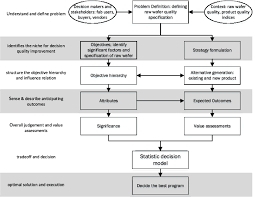

Wafer Yield and Quality Control: Ensuring high wafer yield and quality is crucial for profitability in the wafer business. The yield refers to the percentage of wafers that meet the required specifications and are suitable for further processing. Wafer manufacturers employ stringent quality control measures to minimize defects and maximize yield, as any defects can lead to the rejection of the entire wafer or reduce the functionality of the resulting chips.

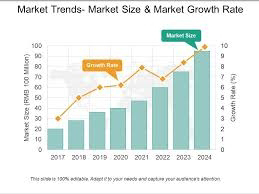

Market Trends and Growth: The semiconductor industry, including the wafer business, has experienced significant growth over the years due to the increasing demand for electronics in various applications. Emerging technologies such as artificial intelligence, Internet of Things (IoT), and 5G networks are driving the demand for advanced semiconductor chips, creating opportunities for wafer manufacturers to expand their businesses.

Regional Concentration: The wafer business is concentrated in certain regions, with major semiconductor manufacturing hubs located in countries like the United States, Taiwan, South Korea, China, and Japan. These regions have established semiconductor ecosystems with a combination of wafer manufacturers, chip designers, equipment suppliers, and research institutions.

Environmental Considerations: The production of semiconductor wafers involves the use of various chemicals and energy-intensive processes. In recent years, there has been an increased focus on adopting more sustainable practices in the semiconductor industry, such as reducing water usage, improving energy efficiency, and implementing recycling programs for wafer manufacturing waste.

Overall, the wafer business is a dynamic and technologically advanced sector that plays a vital role in the global electronics industry. As technology continues to advance, the demand for smaller, more powerful, and energy-efficient semiconductor chips will drive further growth and innovation in the wafer manufacturing industry.

Follow me more

Click on the link 🔗🖇️👇👇

Comments

Post a Comment